Natural Stone Processing

Stone is a versatile material and the experience of watching finished stones which feature diverse colors & shapes, emerging out, are truly mesmerizing.

A process of natural stones begins at the quarry, where a segment of solid rock is being found & blocks are segregated from it by minimizing the damage to stones

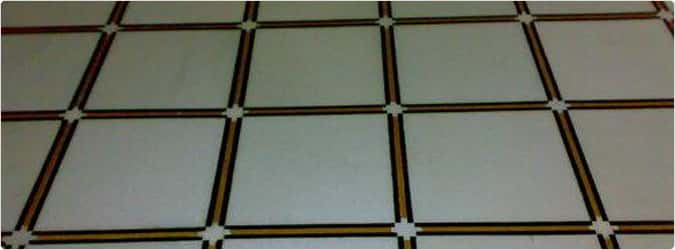

Heavy devices are used for transporting stone blocks from quarry of processing yard, where they are sawed into slabs & tiles. Next sawing trims down the slabs into dimensional stonework.

A work featuring complex nature may be performed on polishing machines, by manually & on profiling saws. The natural surfaced blocks are cut into various pieces, featuring diverse sizes & thickness. After that, a surface is given a finished touch by polishing a texture.

Refined methods through the help of cutting-edge technology, yields superior results than conventional methods.

Through the use of latest technology, a product may be created which can meet international benchmark.

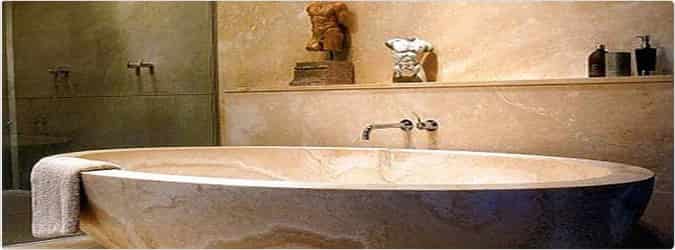

Limestone & Sandstone and are generally obtainable in honed finish while other harder limestone & Marble can be polished.

n order to attain the original pattern & color of a natural stone, polished surfaces are naturally considered at the best alternative among diverse sorts of stone surfaces, since polished surface doesn't alter the inherent nature of a stone.